what size hole to cut for a circular electrical rework box

How to Cut Drywall for an Opening

Updated: Sep. 30, 2019

Cut out drywall holes for electrical outlets with a drywall saw.

This article will show you lot how to cut clean, accurate holes in drywall for electrical boxes and lights. And without making a mess. Follow this advice to cut perfect sized openings—not too big, non too small and without broken corners. Merely if you lot exercise happen to make a fault, we'll show yous how to set it.

Yous might too like: TBD

- Time

- Complexity

- Toll

- A full day

- Beginner

- Varies

Cutting accurate holes

1 of the most frustrating and time-consuming parts of hanging drywall is cutting all those holes for electric boxes and lights. Cutting them too pocket-sized and y'all have to take the piece downward and recut it. Cutting them too big and yous've got a bigger taping job on your hands, or you wind up throwing abroad the canvass and starting over.

Hither nosotros'll testify yous how to cutting electrical box openings in drywall that fit perfectly the showtime time—without broken corners and particularly without being also big. Oversized holes are a hassle to fix and expect tacky with those big plate covers. If you do brand a mistake, cheque out our remedies for getting you lot out of a jam.

Recessed lights

Cutting openings for recessed lights tin be tricky considering you have to measure out over your caput and then transfer the numbers to a sheet that's sitting on the floor. It's so easy to get confused and lay out the openings from the wrong border and wind up with holes cut in the wrong place. Then you lot've got a 55-lb.slice of trash on your easily.

When you're staring at the sheet trying to figure out which end or side to measure from, pantomime swinging the sheet upwards into place instead of doing the mental gymnastics. Then marking on the canvas the side and terminate to pull your tape measure out from. You'll never go wrong.

You lot tin cut openings for recessed lights by laying them out as nosotros show and then cartoon a circumvolve with a compass and simply cut the openings with am electric drywall saw. Only if you take several recessed light openings to cutting out, invest in a circle cutter. It works like a compass and cuts large circles fast and accurately.

Showtime by measuring the front and back and left and right sides of the fixture (Photo 1), so transfer those measurements to the drywall and draw a box to outline the hole. Draw lines from opposite corners to find the exact center (Photo 2).

Side by side tap a small nail through the center bespeak to marker the other side of the drywall. Set the circle cutter to cut about 1/8 in. larger than the fixture, stick the centre betoken in the eye and rotate the cutter while forcing the bike into the drywall surface. The cardinal is to cutting through the paper. It may take a couple of rotations. So repeat on the other side of the drywall and knock out the plug.

Circular boxes

Measure and lay out the boxes exactly as you lot did for the recessed lights . A drywall square (Photo one) comes in handy for marking box positions. Get one at a home center. Draw the vertical lines kickoff, then make horizontal lines by setting your pencil at the right altitude on the square and sliding the square along the finished border.

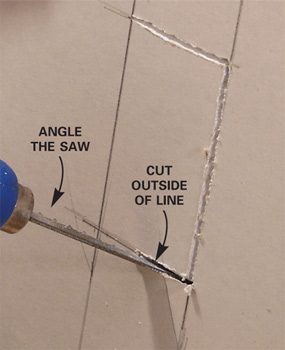

Instead of using a circle cutter, trace the round pigsty with an extra box (Photo 2). If you don't have a box or a compass, sketch the curve freehand. You'll be surprised how accurate you can make it. Then cut the hole with a drywall saw (Photo iii). Information technology's all-time to slightly bending the saw so the opening in the dorsum is larger than in the front end. That way the box volition slip into the opening easier.

If yous cut forth the outside of the lines, the box should fit. But don't presume the holes will slip perfectly over the boxes. Hang the canvas with a few screws that are placed well abroad from the opening. Then gently push the opening over the edge of the box until the sheet rests flat confronting the studs. If you ram habitation screws near a box without careful fitting, chances are you'll bust out a few edges around the box. (See "Oops!")

Avert busted edges similar the plague! To set them, you take to cut abroad all loose paper and broken drywall and fill the gap with setting compound. And so yous accept to apply record and several coats of regular taping compound. Work advisedly to avoid the hassle!

Rectangular or square boxes

You'd retrieve that cut in rectangular boxes would exist much easier than cutting in round ones. Merely they're actually a picayune trickier. If the hole is a bit off, you're much more likely to accident out an entire side. (Run into "Oops!")

Accuracy is especially disquisitional if you take to cut several box holes in the aforementioned sheet. Likewise continue in listen that the electrical code allows only upward to a 1/eight-in. gap around electric boxes, so you can't cut the holes actress large. You lot accept to fill larger gaps with setting compound. And if the gap gets likewise big, you'll have to tape it besides because the outlet cover plate won't hide it. (I've seen it many times!)

To assure accuracy in measuring, keep the tape measure level for horizontal distances and plumb for vertical distances. Even holding the record at a slight angle will cause slight errors in measurements that will cause issues later. Photos 1 – three show the pigsty cut technique. When you're sawing the hole, cut at a slight angle to brand the back of the opening larger (Photo ane).

The opening will be easier to slip over the box and yous'll be less probable to break out corners. Also, score and suspension the fourth side with your utility knife. It's cleaner and easier than sawing, and you lot're less likely to damage the hole edges.

Hang the sheet with just enough screws to concur it in identify, keeping the screws well away from electrical boxes. And so gently push the drywall into place around each box. If the opening doesn't skid past the box, use a utility knife to cleave abroad the sides until the drywall fits (Photo four). So finish screwing off the drywall sail.

Oops!

If the hole isn't cut perfectly and you run screws through the drywall into the framing near boxes, the edges of the electric box may break out the surrounding drywall.

Required Tools for this Project

Accept the necessary tools for this DIY project lined up before you start—you'll salvage time and frustration.

Circle cutter

Required Materials for this Project

Avoid last-infinitesimal shopping trips by having all your materials set ahead of time. Here's a list.

Originally Published: September 30, 2019

lagrangealses1994.blogspot.com

Source: https://www.familyhandyman.com/project/how-to-cut-drywall-for-an-opening/

0 Response to "what size hole to cut for a circular electrical rework box"

Post a Comment